AERATION FOR TREATMENT FACILITIES

Aeration is an integral device that ensures the successful treatment of wastewater. It allows for the delivery of air at the appropriate pressure to optimize the treatment process, including aeration in various types of tanks.

Industrial aerators are capable of compressing air at low pressure. They function as compressors and vacuum pumps and are also used for backwashing filters at water treatment plants.

Modern aerators are designed with a focus on increasing treatment efficiency and ensuring maximum process safety, making them increasingly popular.

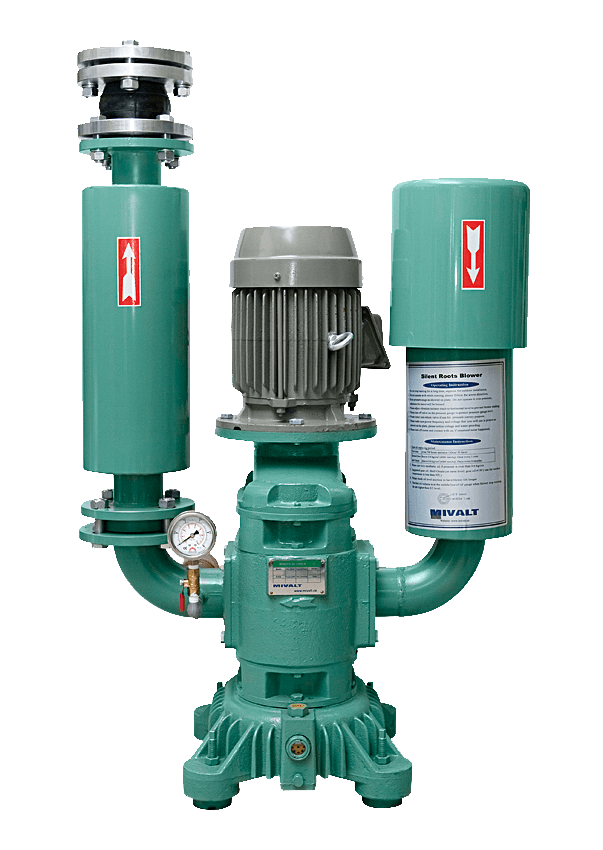

Rotary Air Blowers

Working wheels equipped with profiled gears provide:

Attention is also drawn to the increased service life of this type of device and the minimal frequency of failures.

Non-membrane blowers by NITTO (Japan):

Non-membrane blowers from NITTO (Japan) are modern and highly technological devices distinguished by a high level of automation. This makes their operation exceptionally efficient and simplifies the maintenance process. Thanks to automatic functions, these blowers can independently control and adjust air supply, taking into account the wastewater treatment requirements. This allows for achieving an optimal level of aeration and ensuring the efficient functioning of the treatment processes. Additionally, automation simplifies the configuration and control of blower parameters, providing convenience for the operator. NITTO’s non-membrane blowers meet the requirements of modern and efficient wastewater treatment.

Advantages of NITTO blowers:

| Model | Flow Rate, l/min | Pressure, mH2O | Power, W | Voltage, V | Noise Level, dB | Weight, kg |

| LA-120 | 120 | 200 | 130 | 220 | 48 | 9,4 |

| LAM-200 | 200 | 200 | 215 | 220 | 48 | 12 |

Rotary lobe air blowers SdB (Czech Republic):

SdB rotary lobe air blowers from the Czech Republic are modern devices with a high level of automation, ensuring their efficient operation and simplifying the maintenance process. Thanks to their automatic functions, these air blowers can independently control and adjust air supply, taking into account the wastewater treatment requirements. This allows for achieving an optimal level of aeration and ensuring the effective operation of treatment processes. Furthermore, automation simplifies the configuration and monitoring of the blower’s parameters, making it easier for operators to use. SdB rotary lobe air blowers are reliable devices that meet the needs of modern and efficient wastewater treatment.

Advantages of rotary lobe air blowers:

| Model | Diameter of the pipe, mm | Flow rate at a given pressure

| Noise level, dB | Weight, kg | |||||||||||

| 100 mBar | 200 mBar | 300 mBar | 400 mBar | 500 mBar | 600 mBar | ||||||||||

| m³/h | kW | m³/h | kW | m³/h | kW | m³/h | kW | m³/h | kW | m³/h | kW | ||||

|

SdB4015 |

40 |

1,20 |

0,70 |

0,95 |

0,80 |

0,77 |

0,95 |

0,67 |

1,10 |

– |

– |

– |

– |

58 |

143 |

|

SdB 5015 |

50 |

1,70 |

0,90 |

1,40 |

1,05 |

1,20 |

1,20 |

1,00 |

1,40 |

0,90 |

1,50 |

– |

– |

58 |

143 |

|

SdB 6522 |

65 |

2,30 |

1,10 |

2,10 |

1,30 |

1,90 |

1,50 |

1,80 |

1,80 |

1,60 |

2,00 |

1,40 |

2,30 |

64 |

150 |

|

SdB 7537 |

80 |

2,70 |

1,82 |

2,60 |

2,19 |

2,50 |

2,73 |

2,40 |

3,22 |

2,30 |

3,65 |

2,27 |

3,97 |

70 |

200 |

|

SdB 8055 |

80 |

6,00 |

3,38 |

3,60 |

3,71 |

3,40 |

4,19 |

3,20 |

4,62 |

3,00 |

5,28 |

2,80 |

5,96 |

73 |

240 |

|

SdB 9075 |

100 |

5,60 |

4,71 |

5,40 |

5,23 |

5,20 |

5,81 |

4,80 |

6,52 |

4,50 |

7,33 |

4,20 |

9,63 |

75 |

280 |

|

SdB 10011 |

100 |

7,30 |

6,15 |

6,90 |

6,82 |

6,60 |

8,05 |

6,30 |

9,09 |

6,00 |

10,3 |

5,70 |

11,7 |

78 |

320 |

|

SdB 15022 |

150 |

17,8 |

9,96 |

17,1 |

14,0 |

16,5 |

16,0 |

15,8 |

18,0 |

15,3 |

21,0 |

14,9 |

24,6 |

87 |

650 |

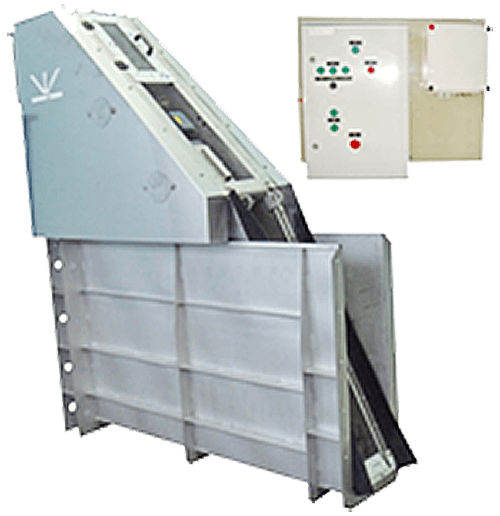

Gratings for capturing coarse impurities

Застосування решіток допомагає знизити ризик забруднення обладнання на очисних спорудах, таких як насоси, аератори і т.д. Вони мають широкий спектр застосувань і використовуються на різних типах споруд, таких як рибні, м’ясні, фарбувальні, паперові, текстильні, молочні, насосні станції і т.д.

Розміри решіток вибираються відповідно до фактичних потоків і умов, що існують на конкретному об’єкті. Вони можуть бути встановлені в каналах різних розмірів, забезпечуючи ефективне утримання твердих часток і недопущення їх проникнення до обладнання. Решітки є важливим елементом для забезпечення безперебійної роботи систем очищення та збереження їх функціональності.

| Type | Size | ||||

| Channel depth, mm | Channel width, mm | Grating height, mm | Grating length, mm | Clearance, mm | |

|

OZ-300 |

300 |

300 |

1200 |

1100 |

2-6 |

|

OZ-400 |

400 |

300-400 |

1300 |

1200 |

2-6 |

|

OZ-500 |

500 |

300-500 |

2400 |

1300 |

2-6 |

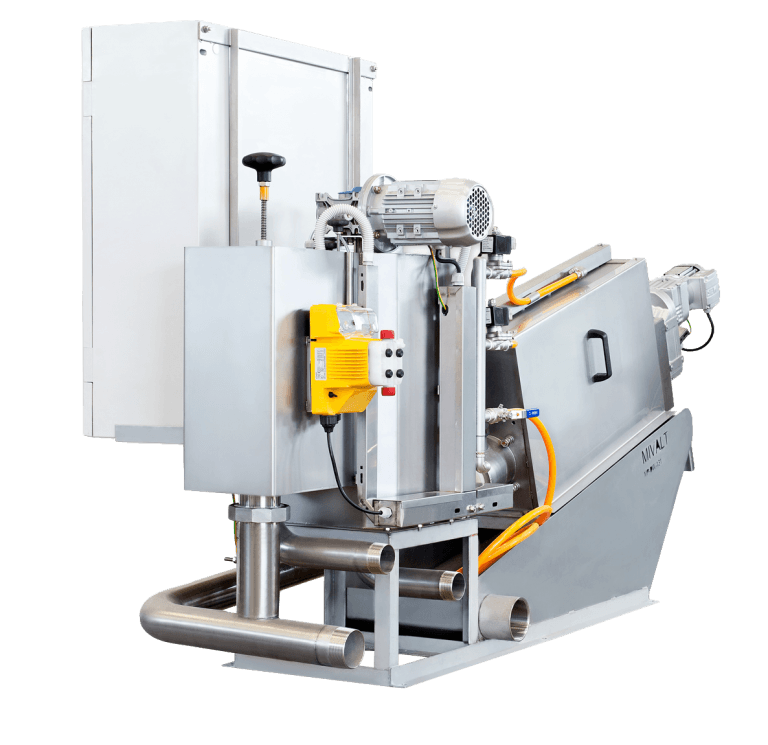

Installation for dewatering excess activated sludge

A screw press is a device used for compressing and dewatering sludge. It can operate automatically with minimal maintenance requirements.

For dewatering excess activated sludge at wastewater treatment plants, especially when processing 100 m3/day or more, it is recommended to install dewatering presses. This is particularly useful when there are no sludge lagoons available. “UKRBIOTAL” company can supply screw presses of Czech production as additional equipment.

The equipment for screw presses includes the press itself with a screw, a pump for feeding sludge from the sludge tank to the press chamber, as well as a flocculant dosing pump.

| Model | Screw, mm | Maximum Flow Rate, m³/h | Power, kW | Weight, kg | L, mm | H, mm | W, mm |

| MPD-131-B | 130 | 3 | 0,2 | 300 | 2200 | 1050 | 640 |

| MPD-201-B | 200 | 10 | 0,65 | 580 | 2600 | 1350 | 750 |

| MPD-301-B | 300 | 30 | 0,8 | 980 | 3100 | 1600 | 820 |